By Terry Foster and Bob Hansen

This article first appeared in the Nov 2013 issue of

Brew Your Own magazine.

Homebrewers are often confused by the terms crystal and caramel malt and are sometimes uncertain as to whether these are basically the same thing and can be used interchangeably, or whether they are quite different animals. Partly this comes from the fact that crystal and caramel malts come in a range of different colors, and that individual products from one maltster may not be identical to those from another producer. They are in fact proprietary products and are often given proprietary names, which only serve to increase the confusion. That’s a pity because when they are properly used they are important cards in the discriminating brewer’s hand. In this story, we’ll talk about how they originated, and what they are, and see if we can’t clear up that confusion.

The first point in this discussion is the fact that these are roasted malts, and the roasting is carried out in a specific manner (there are exceptions as we’ll see later). Crystal malt came first and originated in England, at some time around 1880. The roasting process to produce black malt had been practiced since 1817, when a man by the name of Daniel Wheeler took out a patent on the procedure. Black malt was widely used to replace brown malt in porter brewing, but porter drinking declined during the 19th century as the public developed a taste for pale ales. At the same time original gravities (and therefore alcohol levels) were also falling in Britain, which led to brewers producing lighter, weaker, and less flavorful beers. This trend was further enhanced in 1880 when a new law was introduced which allowed brewers to substitute some base malt with sugar.

So, I presume that some bright maltster saw that there was (or would soon be) a need for a malt additive that could be added in small amounts to improve the body and flavor of pale beers, just as black malt served to give porters and stouts their characteristic flavors. So, since this maltster had already had a roaster, he or she experimented with different levels of roasting and came up with crystal malt. The new product met with approval from brewers and went from strength to strength through to the present as British beer original gravities continued to decrease throughout the 20th century. Crystal malt is now the predominant colored malt used in Britain and is used in most ales brewed there.

Malting techniques improved considerably over the same period, and maltsters learned to produce crystal malts with different levels of color and flavor and suitability for use in the whole range of British beer styles (including pale lagers). One result of this is a big part of the confusion referred to in the first paragraph. For there was a resurgence in homebrewing in Britain in the 1960s, and the country’s malt extract producers were quick to see the opportunity and to develop products suitable for homebrewing. Having established a base over there, they were in a good position to expand into the U.S. homebrewing market when the hobby started to be legalized in 1978. And that brought popularity for British crystal malt too, since it was easy to add a little extra to an extract recipe by steeping some crystal malt and adding that to the brew. This at first over shadowed similar American products because by some quirk these were known as caramel malts, not as crystal. But soon these caramel malts became available to homebrewers, many of whom seemed to have thought, “If they’re called caramel malts they must be different from British crystal products.”

They are not different, of course, for with certain exceptions caramel malts are crystal malts, and the terms are often used interchangeably in the malting trade. Many producers especially English and Belgian, (such as Muntons, Simpsons, Hugh Baird, Crisp, Thomas Fawcett, Castle) refer to them as crystal malts, though some (Briess, Weyermann) call them caramel malt. Though there are unique house flavors particular to every specialty maltster and varietal (and quality differences of course), the truth is most caramel malts produced by the same method have very similar flavor at the equivalent Lovibond color. This is because the flavors produced are mainly a function of the process.

There are, however, two distinct processes for producing caramel-type malts, namely kilning and roasting. It’s important to understand the differences between them and find out what your supplier is using so you can properly formulate your beer. This is sometimes difficult as terminology is not consistent from supplier to supplier and is further complicated and obscured by trade and brand names.

The basic information you need to know to differentiate these two malts is this: Caramel malt is applied to both kiln and roaster produced caramel malts, but the term crystal malt is normally reserved for caramel malts produced in a roaster. Logically, the term crystal malt should be reserved to describe malts that are truly crystal in that they exhibit even and consistent crystal like, glassy kernels which is possible only by roasting. If we accept this terminology as being appropriate, then it should be realized that all crystal malts are caramel (type) malts, but not all caramel malts are crystal malts.

Which malt is which?

So, what’s the difference between roasted crystal and kilned caramel malts? This becomes clear when we look at the difference in the two processes. Let’s start with crystal-type caramel malts produced in a roaster. To start, sprouted barley after four days of germination is fed directly into rotating drum roasters similar to those used to produce coffee or cocoa. The malt is still “green” and growing and contains about 42% moisture. The drum is rotated and slowly heated to bring the grain temperature up to starch conversion temperature, roughly 150 ºF (65.6 oC), just as is done in the mashing process in the brewery. As in mashing, the native amylase enzymes activate and turn the wet starch in the kernel into simple sugars. Because there is so little moisture, this gooey sugar stays inside the kernel. It’s like millions of little mash vessels with wort trapped inside. Once conversion is complete, the maltster turns up the heat and begins drying out the malts. Very quickly the sugars are concentrated and the temperatures are taken high enough (>300 oF, 149 oC) to achieve carmelization of the sugars.

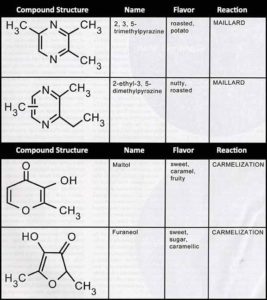

Caramelization is a term used to describe interactions between sugars under the influence of heat. This is really pyrolysis of sugars, and does not involve nitrogen compounds, as occurs with the so-called Maillard reactions, which more commonly occur in kilning of malt. Thus true caramelization is responsible for much of the color and flavor associated with crystal malt. These flavors are “pure” candy-like caramel flavors since they are subjected to a shorter and more complete conversion time as well as a controlled and rapid increase to high temperatures during the roasting process. Crystal malts have been through a truer caramelization process than a kilned caramel has, and therefore will have flavor attributes similar to candy such as caramel and toffee. Some of the main compounds and their flavors are shown in figure 1. Note that these compounds do not contain nitrogen as they come from the sugar-sugar interactions of caramelization. These clean, sweet candy like flavors present themselves unadulterated by biscuity, bready or other baked flavors more associated with the Maillard reaction and kilned caramel malts.

The maltster can control the level of caramelization and color of caramel/crystal malt by varying the time and temperature of heating of the sugar-containing grain. Consequently most maltsters offer a range of these malts, with increasing caramel levels and color increasing from pale gold to a dark red-brown hue, accompanied by increasing intensity of flavor. It should be understood that these malts are all produced in individual batches, and on a much smaller scale than that for regular pale malts. In one sense, crystal/caramel malts are very much a “craft” product. When you remember that the whole malting process starts with a natural product, barley, which varies from year to year and growing place to growing place, you will understand that producing malt of consistent quality is no easy task.

That is because although the roasting process takes up to four hours, the caramelization stage of the process is quite rapid and takes place only during the last 15-20 minutes of the procedure. The green malt used for crystal/caramel production has not been kilned and can germinate further, depending upon how long it stands before roasting, adding yet further possible variations. The extent of caramelization is therefore controlled by an experienced roaster relying upon taste and color comparison with standard samples. The finished product will be checked by various scientific tests for consistency and color, but these take too long to complete for them to be used during the rapid stage of the process. Each batch is a little bit different, each produced by hand and relying on the roaster’s skill in making a consistent product with an ever changing raw ingredient . We brewers often take the quality of crystal/caramel malts for granted, and do not reflect enough upon the skill and science required to produce them.

On the other hand, the term “caramel malt” can also refer to malts dried in a kiln, rather than being roasted. These malts have been treated at much lower temperatures than that of crystal malts as well as more variable temperatures due to a larger surface area. Due to the location of grain in the kiln bed and the temperature of the kiln this creates a mixture of malts, some of it with the glassy, caramelized center typical of caramel malt, but some with the malty, mealy character typical of high dried malt. The top layers of grain are subjected to quick drying under moisture and temperature conditions which does not permit the formation of crystal malt but does allow for a high temperature, dry environment to produce Munich malt. Conversely, the inside layers of the bed are not penetrated as easily by the airflow required to dry the grains. These conditions create an environment that is high in moisture and at high temperature, allowing for continued conversion of the starchy inside of the malt kernel. This conversion creates simple sugars which caramelize in the high kiln temperatures, just as happens in a roaster. Therefore, unlike true roasted caramel malts, kilned caramel malt is not homogeneous, and a significant proportion of the kernels from it will not have the same glassy appearance as the roasted caramels. The kiln-dried versions will have some candy-like caramel flavor but will also be “adulterated” with the intense, malty flavor of high temperature kilned malt.

Many beers and brewers do quite well with the mix of caramel/maltiness that comes from a kilned caramel malt. This has obvious advantages for commercial brewers looking to simplifying grain inventories. For example, Caramel Munich and Carmel Vienne are two products produced by Briess Malt & Ingredients Co. meant to be used by brewers in this way. Since Briess typically does not manufacture kilned caramels, they achieve the same effect by blending caramel malts with Munich or Vienna malt. While this process creates a similar product to that obtained by direct kilning, the result is a more consistent product.

There are many combinations that can be made using this idea, producing a range of hues and flavors suited to many different beer styles. The all-grain home brewer might see things differently and would want to add Munich and caramel malts separately if he was looking for more control with this type of flavor combination. Malt extract brewers would have to carry out a partial mash with this type of mixture, or kilned caramel as they contain starchy endoperms which must be mashed. They might prefer to simply stick to the use of straight caramel or crystal malt and an extract containing Munich malt.

Types of caramel malts

Weyermann, Dingemans, Castle, Muntons, Crisp, Briess (a European immigrant) and most European specialty malt producers produce caramel type malts in a roaster. How do you know which type of caramel malt you have? Well the name doesn’t always help much, since trade names are often prefixed by the term “Cara”, which may be applied to both roasted and kiln-dried types. But no craft or home brewer should ever overlook the importance of taste, sight, and smell.

So the first thing to do is to simply look at a number of kernels. Roaster produced crystal type caramel malt will have 90% + of the kernels containing only glassy crystal like converted sugar. Kiln produced caramel malt will have a large proportion, usually about 50%, of the kernels mealy and starchy on the inside, just like high dried or Munich malt. (See pictures of cross cut malts). The second thing to do is to taste a kernel or two. Depending upon the degree of roasting, roasted caramels will have candy, nutty, or even raisin-like flavors; kiln-dried caramels may show some of these flavors, but to a lesser extent, and they will be masked by the grainy malty notes from the grains, which have not been caramelized.

As stated above, for the same Lovibond color, roasted caramel/crystal malts from different maltsters are comparable in their effect on beer, and for the record there appears to be no significant difference between those produced from 2-row or 6-row barley. There are a wide range of these malts available to craft and homebrewers, although European, and especially British products offered are often toward the high end of the color range, from 50-60 oL up to as high as 140 oL. Muntons offers two crystal malts at roughly 65 and 170 oL. Of U.S. suppliers, Briess has an extensive series of caramel malts ranging from 10 oL to 120 oL, which contribute flavor intensity from mild caramel sweetness to more intense toffee and raisin notes. Great Western Malting also produce quite a wide range (from 13-17 oL up to 145-155 oL).

Color and hue of caramel and crystal malts

It has been shown that the color contribution to wort and beer of all caramel and high-dried malt is nearly exactly the same. That is the coloring compounds generated in these processes absorb light in the same way. What is different is the amount of these compounds contributed by each type of malt. Darker malts contribute more color compounds and make it possible to achieve darker colors and the associated unique hues.

Choosing a caramel malt

There is really more than meets the eye to finding a malt or combination of malts that will give you the flavor and other characteristics you desire while having the correct amount of coloring compounds.

As an example, say you wanted an Abbey-style beer to have a deep, rich mahogany color. This color is achieved by having a 35 oL beer made with the red-hued malt from caramel roasting or kilning processes. If you tried to do it with a 10 oL caramel malt you would have to use 3 lbs of caramel malt per gallon and it would be 100% of your grist. Impossible right? Use caramel 60 and it will be 17% of your grist. Use caramel 120 and it will be 8% of your grist. See why we say you need to use caramel 120 to get a mahogany shade in your beer? It’s not because it’s color is different than what you get from caramel 60, it’s that you need so much of the coloring compounds that it’s impractical to do it with any other malt. Plus the darkest caramels are the only way of providing the complex, burnt sugar and raisin notes that have become associated with this beer type.

For a less straightforward example, say you are formulating an American amber lager and you want the color to be 12 oL. There are a host of caramel malts that could be successfully used and the differences are subtler than the above example. If you wanted a beer along the lines of an American style Märzen/Oktoberfest, the malt character should be, “Light toasted not strong caramel (though a low level of light caramel is acceptable)” according to Great American Beer Festival (GABF) style guidelines. To be very malty you could use 50% Munich 10 oL or 25% Munich 20 oL with Vienna or base pale malt.

The same beer could be formulated slightly less malty and more to style with Vienna or base pale malt, 20% Munich 10 oL and 5% Caramel 60 oL. Either a crystal 60 oL or a kilned caramel 60 oL or caramel Munich 60 oL would work here, with the latter versions providing a slightly stronger malty note. It would not be within style guidelines if you formulated this beer with base pale malt and crystal malt alone, unless the base malt carried a strong malty note, such as 90% Vienna malt and 10% crystal (or kilned caramel ) 60 oL. This last example is the most traditional recipe according to George Fix, author of Vienna-Marzen Oktoberfest, which is part of the Brewing Classic Styles series.

If you wanted a beer along the lines of an American-style amber lager or California common, traditional GABF style guidelines would favor crystal-style caramel malts as these beers have, “A noticeable degree of caramel-type malt character in flavor and often in aroma.” And “low to medium low” malt character. Using 10% of a caramel Munich 60 oL or 10% kilned caramel 60 oL to get the desired color may result in too strong of a malty character for style. Your best choice would be a smaller proportion, say 5-7% of a 60 oL caramel/crystal malt.

Know your crystal (or caramel)

We have endeavored to clarify the situation with crystal and caramel malts and to explain the differences between the wide ranges of products on the market. These are products of inestimable value to the craft and home brewer, and can help you establish a signature for your beers. Commercial brewers often use these malts to adjust the color of their brews and we have given some examples of this approach. However, these malts are also an important flavoring tool, especially in ales, porters and stouts.