As we enter into the hottest and most humid weeks of the year, the management of temperature and drying conditions are top of mind for many maltsters. Striking a balance between drying rate and ideal applied temperature is often a day-by-day and hour-by-hour evaluation by the maltster and the production team. At a glance, it may seem straightforward, more heat = more drying, right? Not exactly…

Our malting processes are finalized with 2 types of drying: Kilning and Roasting. Each of these drying steps is unique.

Kilning is a process that targets progressive yet gentle drying over a longer period. To optimize energy consumption and reduce heat loss, Briess utilizes a double-deck kilning system, drawing high volumes of air at incremental speeds through both layers. This process allows for two things: Forced drying and curing to occur on the lower deck of material while utilizing that drier air for additional moisture removal on high moisture product on the upper deck. With a high dewpoint in the incoming air stream, the rate of drying is reduced at the same temperature input. An increase in applied air temperature at the wrong time could lead to detrimental effects on enzyme levels or an undesirable increase in color. A maltster makes careful and calculated adjustments at each step to keep these values in balance while maintaining the ideal amount of time to promote flavor as well.

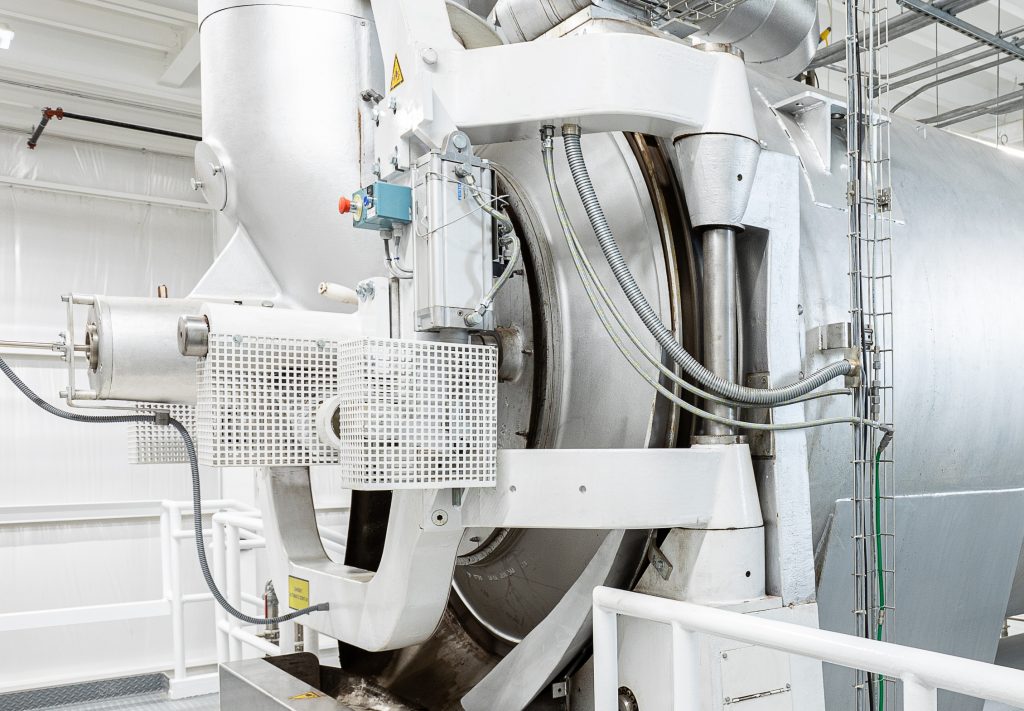

Roasting is a process with the intent of heating to much higher temperatures in a shorter time to drive different types of reactions. Unlike kilning, which dries the entire quantity from germination in a single batch, roasting is a combination of batch and continuous, creating additional challenges with controlling the temperature of the still germinating green malt. Our roasting systems are state-of-the-art and designed with various layers of air flow and heating controls. This flexibility allows us to make necessary adjustments to the recipe to ensure adequate conversion without the risk of overheating the product or slowing the drying rate to a point that will not produce the right color outcome. The maltster must monitor both the raw material moisture and temperature as well as the roasting environment’s relative humidity and temperature to make the right process adjustments.

Each of these efforts are executed with the end goal of ensuring high quality and consistency of all the specialty malts Briess produces. It’s a labor of love for all of us at the Manitowoc Facility. Malting has always been a process that has had to adapt to the seasons, and even with advances in automation and process control, sometimes Mother Nature still has the upper hand. But that is when we use our expertise to work with the environment we are given. Since the art of drying is half of what we do as maltsters, we welcome the challenge. We can take the heat, bring it on summer!