Since Briess introduced Crystal Red® Malt a little over a year ago, I have really enjoyed seeing the reactions of brewers as they sample the malt. It’s been interesting – as they chew the malt, it’s almost as if I can see the light go on in their minds. Suddenly, we’re discussing tweaking recipes with Crystal Red® to achieve a long-sought-after color. Inevitably, the question comes up – how does this differ from other red malts that are already out there? What makes Briess Crystal Red® Malt different?

Not all Red Malts are the Same

After all, there are numerous malts out there with the term “red” in their name. But not all red malts are the same. In fact, the red malts that I came across in my research are all quite different. Usage rates of these red malts vary widely; some can be used as base malts and others at much smaller inclusion rates. Even the sensory descriptors seem all over the place – I see “nutty,” “malty,” “sweet,” “intense burnt toffee,” and quite a few mentions of melanoidins. It can be a little confusing, so let’s start with exactly what Crystal Red® Malt is and how it is made.

What is Crystal Red®?

The name alone really tells the story of this malt. It is a caramel malt that will impart deep red color and hues. The barley for our Crystal Red® Malt follows a very similar path to many of our other malts. The barley – after cleaning and sorting – moves from our storage bins to our steep tanks, where it is woken up as moisture is driven into the kernel. This is where the modification process starts. It is then “steeped out” into our germination compartment where it will stay for four days, as our experienced maltsters use tools such as temperature, humidity, airflow, and turners to achieve the desired result.

looking for barley chit – the first sign of a growing seed.

Drum Roasting Crystal Red®

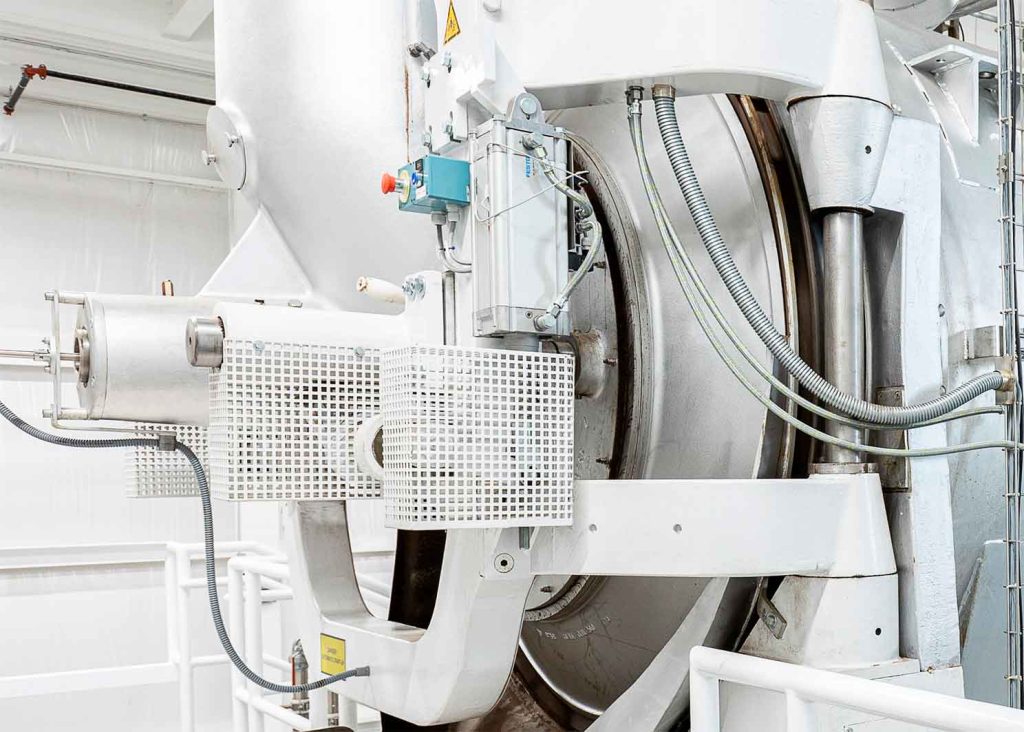

From here, the green malt will go into one of our drum roasters. Why a roaster and not a kiln? A kiln cannot reach the intense temperatures needed to make a crystal malt. In addition, the bed in a kiln is so deep that even if you could reach those temperatures, it would be very difficult to make a homogenous product. With a roaster, the malt reaches uniformity after only a couple of revolutions. As the drum-roaster turns, the temperature gradually rises. The malt is stewed and held at saccharification temperatures, allowing the enzymes present to convert the starch in the kernel into simple sugars.

In essence, we are performing a mini-mash in the roaster. Once the saccharification step is complete (one indicator is that you can squeeze a kernel between your fingers and it will pop like a pimple (not the greatest visual, but a good analogy), the temperature is raised, malt begins to dry out, and the sugar inside becomes more concentrated.

engineered specifically for roasting malt and barley.

Is it Crystal or Caramel Malt?

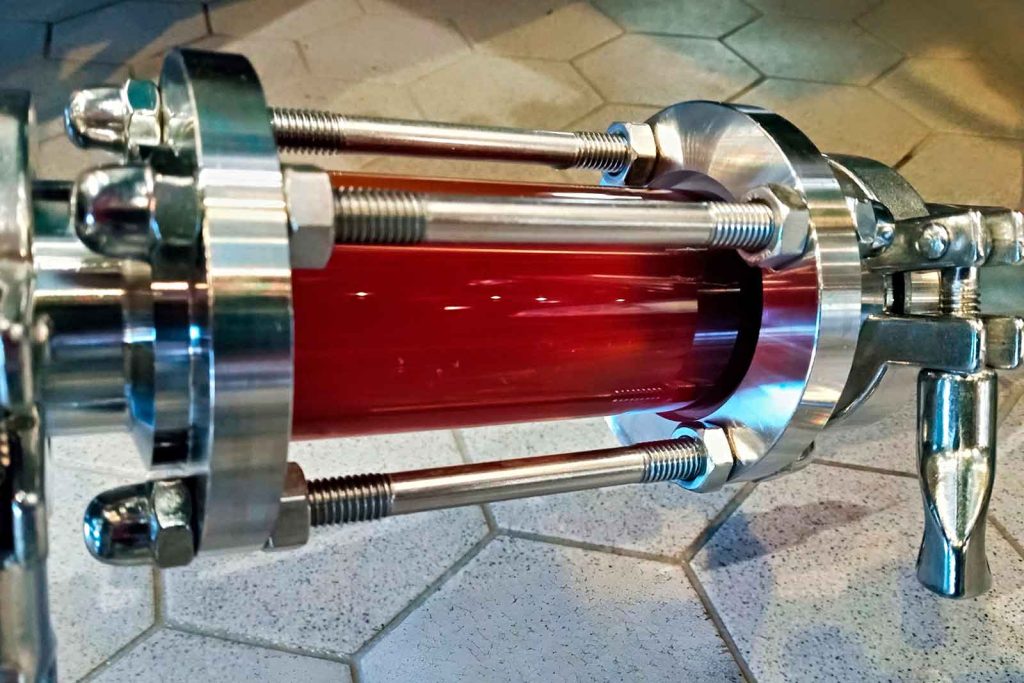

As Terry Foster and Bob Hansen explain in the article, “Is it Crystal or Caramel Malt?” caramelization is a term used to describe interactions between sugars under the influence of heat. The moisture is driven out of the kernel and the sugar hardens and crystallizes. Through the pyrolysis of sugars, the malt develops color and flavor. The roaster operator can control the development of color and flavor with time and temperature. Crystal Red® Malt is deeply roasted to color in the range of 180-200 SRM. It’s hard to achieve this level of color without getting into coffee and bitter roast flavors, but with Crystal Red® Malt, you can expect flavors of toffee, raisin, and burnt sugar, depending on the usage rate, with color ranging from light orange to deep ruby red.

How does Crystal Red® Malt Differ from other Red Malts?

First, there is no diastatic power in Crystal Red® – the intense heat involved has long since denatured and destroyed any enzymes present. Therefore, it cannot be used as a base malt. Because of the intense crystallization of the kernel, a small inclusion can go a long way in terms of color. Crystal Red® Malt is normally used between 1%-7% of the grain bill.

In other words, you get the best bang for your buck in terms of color, especially if you are looking for ruby red hues – no need for a 100% or 25% inclusion rate. Try a series of hot steeps and see for yourself. If you’re making an Amber Ale, Red IPA, or Bock, or you just want to tweak the color of a current recipe, give it a try.

Recipes Brewed by Briess Technical Services Team

Enjoy a variety of recipes formulated in the Briess Pilot Brewery to showcase the intense red color that can be achieved using Briess Crystal Red® Malt.

Scottish Ale (“Brewhouse” Recipe)

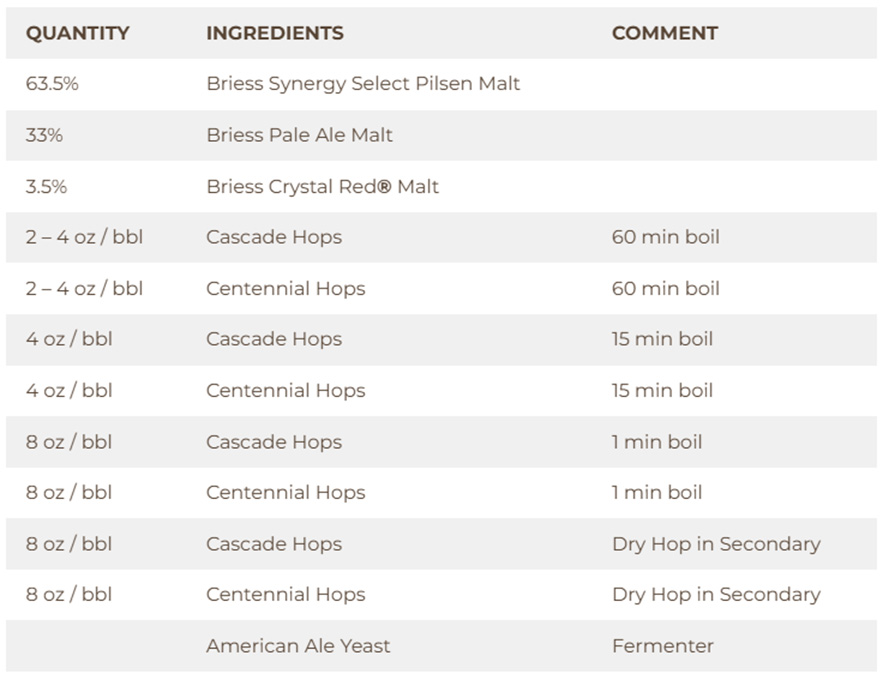

All Red! All Red! All Red! Pale Ale (“Brewhouse” Recipe)

American Pale Ale is formulated to showcase the intense red color that can be achieved using Briess Crystal Red® Malt.

OG: 1.058

FG: 1.015

ABV: 5.0%

IBU: 45

COLOR (SRM): 17

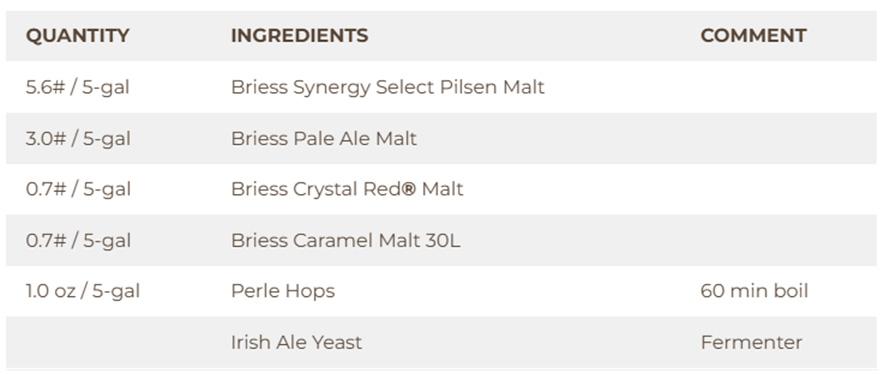

All Red! All Red! All Red! Pale Ale (“Homebrew” Recipe)

American Pale Ale is formulated to showcase the intense red color that can be achieved using Briess Crystal Red® Malt.

OG: 1.058

FG: 1.015

ABV: 5.0%

IBU: 45

COLOR (SRM): 17

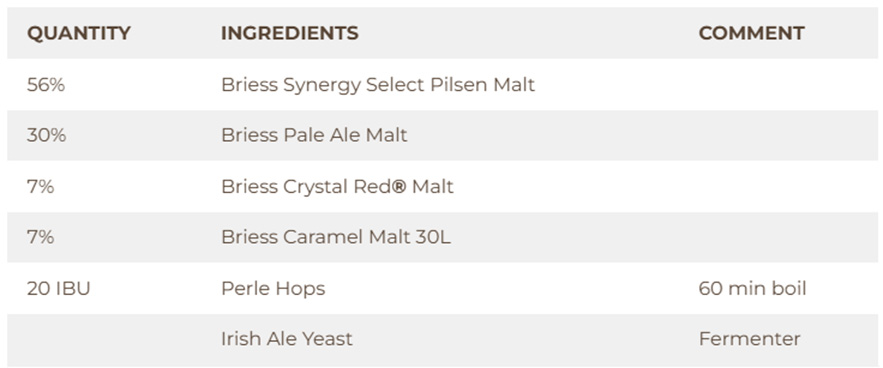

Buzzing the Tower (“Brewhouse” Recipe)

Caramel sweetness and a soft molasses aroma are balanced with a drying finish using Briess Crystal Red® Malt.

OG: 1.052

FG: 1.013

ABV: 5.0%

IBU: 20

COLOR (SRM): 26

Buzzing the Tower (“Homebrew” Recipe)

Caramel sweetness and a soft molasses aroma are balanced with a drying finish using Briess Crystal Red® Malt.

OG: 1.052

FG: 1.013

ABV: 5.0%

IBU: 20

COLOR (SRM): 26