At Briess, we have a wide range of equipment for malting, including large tanks for steeping, conveyors for moving grain, fans, heaters for drying, and the list goes on. Malting is a very simple concept – sprouting, growing, and drying grain, which is done in a very complex way. The malting process has evolved to include complex monitoring systems, data logging, and recipe-driven automation. Malting new products, transitioning between crop years, assessing new varieties, and exploring new grains for malting require an extra level of attention in the malthouse. Predicting how a complex process will go can be very difficult when trying to produce consistent and high-quality malt. In Briess’ Center of Malting Excellence, we utilize small-scale pilot malting to more accurately predict how things will progress as they move through the malthouse.

Early pilot malting was very manual, with repurposed equipment that made process control a bit of a challenge. Despite the challenges, we saw very promising results. The results we found gave us an excellent insight into making the appropriate process adjustments before we scaled up to full-size batches. It also helped us develop a few new products. After the initial success, we invested in a small-batch malting unit, allowing us to process 4 – 500 g samples each week. This purpose-built malting unit has excellent process control and automation allowing us to create conditions similar to a full-size malthouse with very little manual interaction, other than evaluating how the process is going. This was another step forward for evaluating raw materials, assessing process changes, and additional research for various projects. Because of the small size of the samples, there are still limitations to how conditions compare to what is occurring during full-scale production.

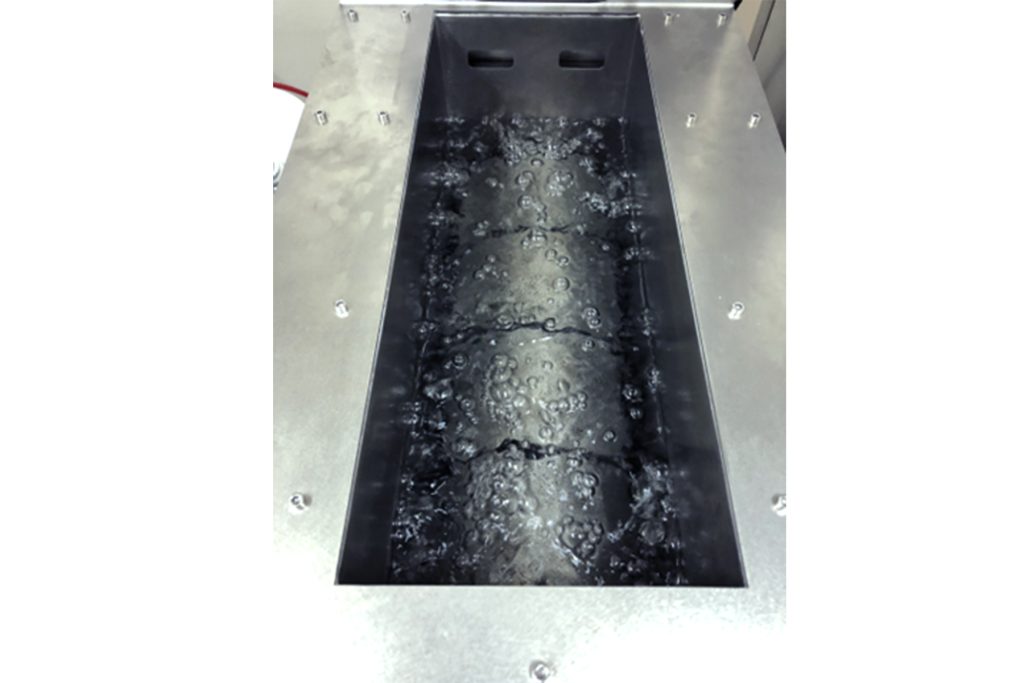

With this in mind, we added another tool to our malting arsenal – a 50 kg malting unit that will help bridge the gap that the 500 g micro-malter cannot. The added size of the sample more accurately mimics how changes in conditions affect the grain. This unit also has all the necessary process controls to adjust and monitor the conditions the grain is experiencing. This will help us make proactive adjustments to recipes before scaling up to production batch size. Additionally, this larger unit produces enough malt that we can do pilot brewing in our research brewery, allowing us to evaluate the effects of new malts or process variants all the way to the finished consumer.

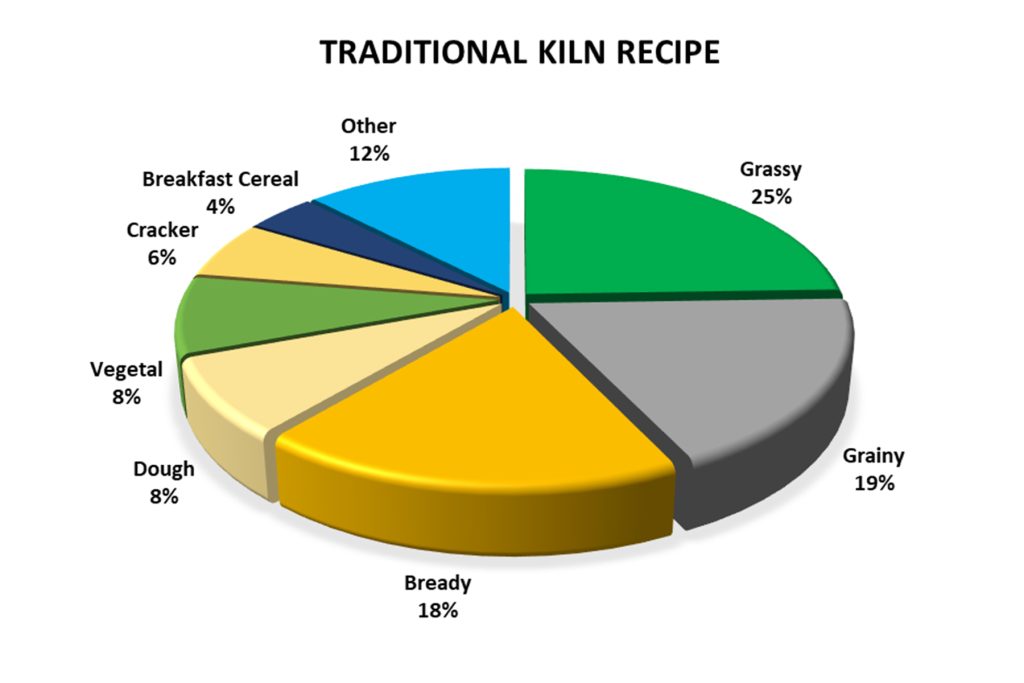

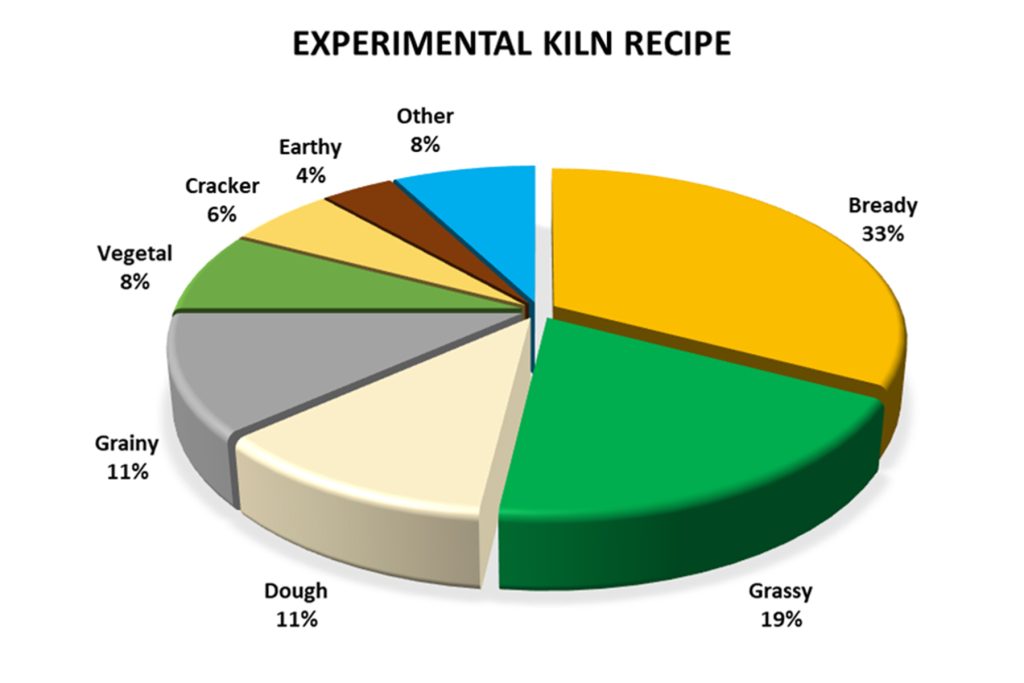

The unit has already proved its value in some of our flavor-driven recipe research in kilning. Utilizing green malt from the same steep and germination process, we compared how different kilning processes can promote different flavor formations. Using a more traditional recipe, and then making specific adjustments to the processes, we can utilize our sensory evaluation team to determine if the changes result in flavor differences. Data from our sensory team confirmed that these minor adjustments can result in significant flavor impacts. We were able to adjust the recipe to promote bready character while decreasing the prominence of the grassy and grainy character and achieving the same analytical specifications.

Having small-batch sizes allows us to run more experimental recipes to improve our process, understand how changes will affect our finished product, and ultimately, lead to better reproducibility and improved quality. In addition to improving existing products and processes, the 50 kg unit gives us the ability to conduct research and development on new products. The smaller scale mitigates the threat of having an entire production batch fail, allowing us to try more extreme processes and pushing the limits of the flavors that can be created in a traditional malting system. We’ve been trialing new recipes and processes since the unit arrived, and we’re planning to release the first product designed on the unit in just a few months!